BMW Spartanburg Factory Tour

During this factory tour of the X3 and X4 assembly line, I could not help but to keep looking around for the rest of the facility. The loud parts., The hot parts. Places where workers are wearing the typical combo of HazMat + X-Ray lead vests for safety.

But in fact, these areas were nowhere to be found. This is partly due to the extremely cutting-edge processes employed in Spartanburg, but also because some key components are handled off-site: including engines from Germany and stampings from Magna Steyr’s facility just down the road.

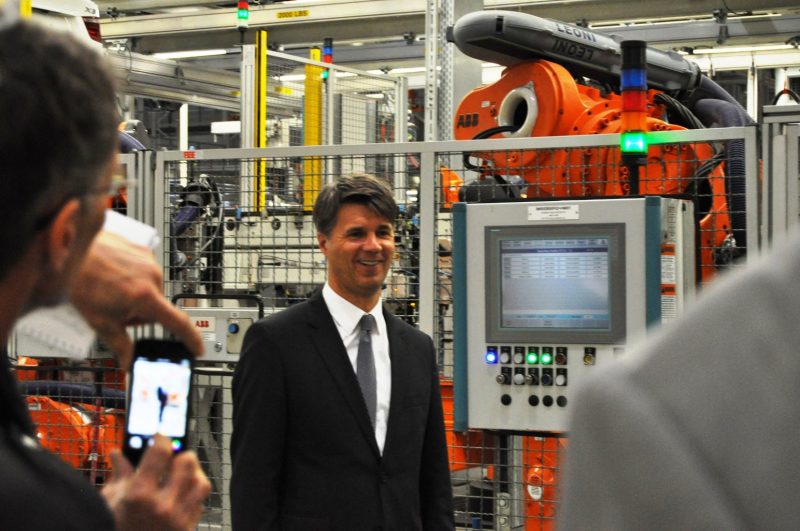

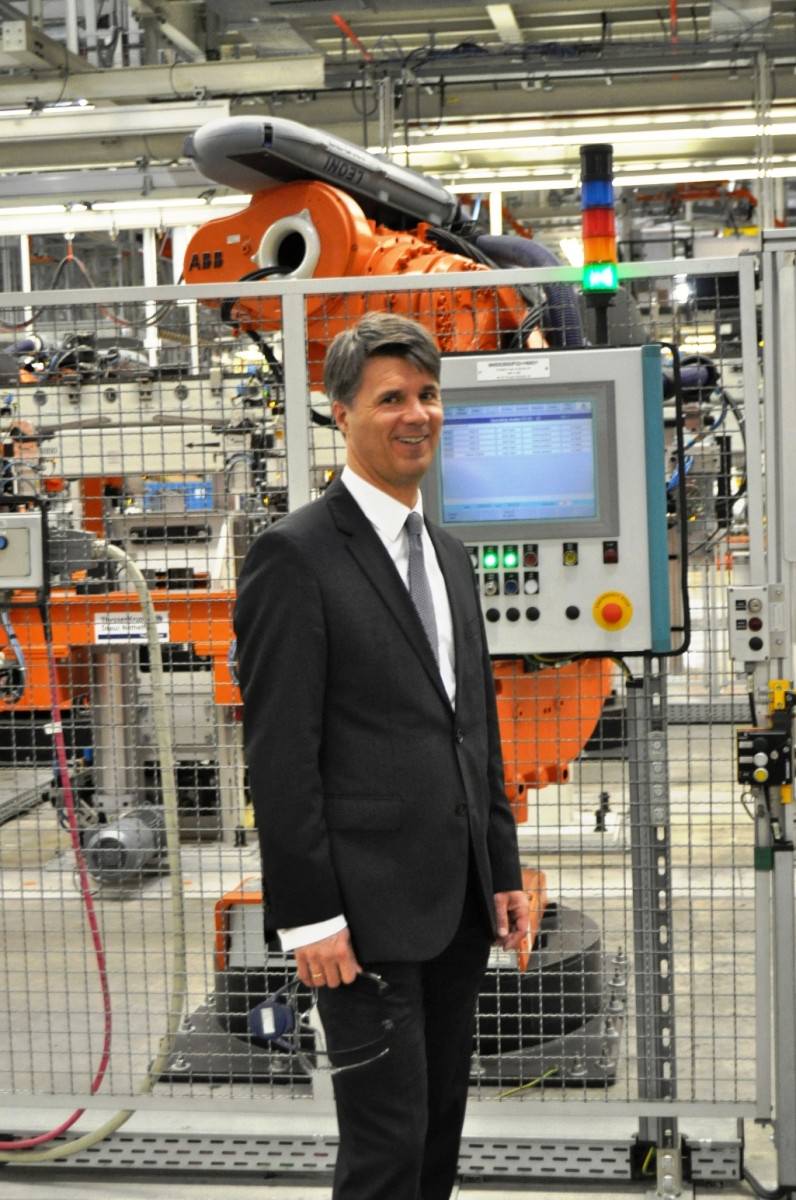

This model factory’s key visionary? BMW Group Board executive Harald Kruger, who is shown below in detail (and many more times in the big photo section a few paragraphs down!)

As a result, the X3 and X4 facility is the epitome of modern assembly. We wore eye and ear protection, as is standard for anyone on any factory floor, but it could not have felt more serene or calm inside this air-conditioned behemoth of a building.

Extra-tall ceilings, some natural light, and loading dock doors just 100 paces from the actual moving lines? Unheard-of!

BMW calls this a finger feeder type strategy, allowing for 80-percent of the parts to be delivered on a just-in-time basis. This means no inventory warehousing, and a far more rapid and efficient build.

How efficient? Quick facts:

-

50-percent of the Spartnburg factory runs on reclaimed natural gas from the Palmetto waste disposal facility (~15 miles away)

-

This saves more than $5M annually in energy costs

-

-

A complete X3 or X4 rolls off the line every 115 seconds

-

The factory is a forklift-free-zone, with little humming trollies that run on hydrogen-fueled battery packs

-

This saves time versus changing the pack or charging the hand trucks 3X daily — just a blast of super-cooled H2 to juice them up in 30-seconds

-

-

Build time is just 22-hours, about 14-hours-less than Volkswagen boasts for its latest Golf models

Please enjoy this photo tour of the Spartanburg X3 and X4 plant, which is twinned with the X5/X6 and X7 facility just across the green lawns in between.

Tours are closed to the public at the moment following the re-tool for the new X3 and X4, but are expected to re-open in by May 2014.

Further details are available at this link.

https://www.bmwusfactory.com/zentrum/tours/guided-factory-tour/

Original Photography from Plant Tour

Tom Burkart is the founder and managing editor of Car-Revs-Daily.com, an innovative and rapidly-expanding automotive news magazine.

He holds a Journalism JBA degree from the University of Wisconsin – Madison. Tom currently resides in Charleston, South Carolina with his two amazing dogs, Drake and Tank.

Mr. Burkart is available for all questions and concerns by email Tom(at)car-revs-daily.com.