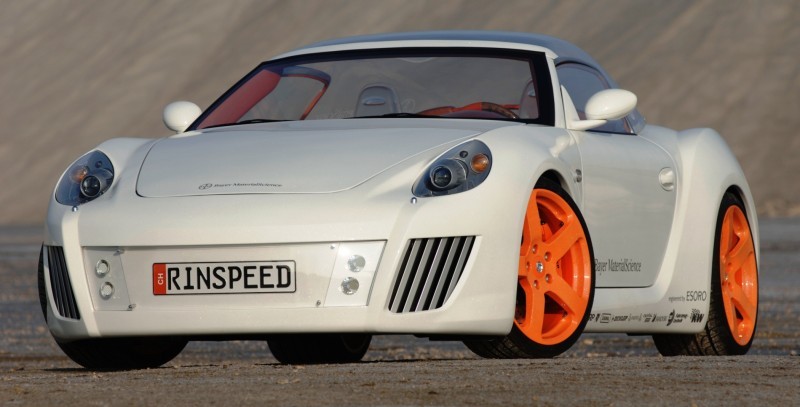

This concept from RINSPEED in 2006 is actually quite magnificent.

A clear polycarbonate hardtop and a variety of innovative supplier solutions round out what is a very intriguing concept car from RINSPEED.

The rear fenders and nose treatment with Ferrari 612 lighting elements is interestings, but the RINSPEED ZaZen is absolutely hideous from the pure nose and tail angles. An unusual and sloppy mess of amateurish block shapes.

2006 RINSPEED ZaZen

Rinspeed “zaZen”

Rinspeed and Bayer MaterialScience jointly develop new concept car

“zaZen” – Automotive enlightenment on four wheels – Revolutionary lighting technique and

transparent hardtop at the Geneva Motor Show

February 28, 2006, will mark the world premiere at the Geneva Motor Show of the

Rinspeed concept car, “zaZen”, created by the famous Swiss designer, Frank M.

Rinderknecht. It represents his vision of the car of the future and will be showcased as a

kind of “automotive enlightenment” on four wheels. The vehicle was produced in

cooperation with Bayer MaterialScience, one of the world’s largest plastics producers. It

also embraces a technical revolution in car manufacture, with the transparent backlite

being turned into a luminous holographic area. As if from nowhere, the third brake light

shines out of what looks like a floating transparent hardtop.

The world premiere of the “zaZen”, with its holographic brake lamp and smoothly

contoured, transparent, one-piece roof dome made of high-tech Makrolon, marks the

beginning of a new era in lighting technology in vehicle design. For Ian Paterson, who is

responsible for innovation on the Board of Bayer MaterialScience, this novel lighting

system represents a small step on the way to building the car of tomorrow: “Together with

Rinspeed, our goal is to get people thinking about the car of the future.

‘

We contribute our

high-quality materials and the combined creative know-how of our engineers.”

The name of the new concept car – “zaZen” – has been carefully chosen by Rinderknecht:

“After all, Zen – borrowed from Buddhist teaching – is a special form of perception: You

only get there if you are prepared to give up preconceived ideas.”

Both partners went out

of their way to emphasize that a concept car presented at a motor show can only be a

snapshot taken from an unceasing development process. For example, the work on the

switch-on/off transparency for three-dimensional forms is always ongoing.

The breathtakingly designed vehicle concept was born at the Swiss engineering

specialists, Esoro, from one single vision and many imaginative ideas.

The entire roof dome down to the belt line is made of Bayer’s transparent Makrolon polycarbonate. A

glass-clear elastic sealant from Revoflex AG has been used to achieve an optimum joint

with the body. The striking hardtop is light in both senses of the word. Not only does it

appear to float airily above the rather chunky body, it is also weighs many kilograms less

than glass – not that it would be possible to make it from glass in the first place.

The lightness of the roof construction ties in with the surface coating of the “zaZen” – a

white mineral shade based on the Bayer raw materials, Desmodur and Desmophen.

It is certainly not gaudy, but unassumingly beautiful through the millions of tiny precious

Swarovski crystals protected by a self-healing polyurethane clear coat. This so-called

“crystal skin” finish was developed and applied by the Austrian surface coating specialists,

Karl Seelos. The Lesonal company was responsible for producing a perfect substrate.

In a nutshell, the future driver can expect to find a muscular body in a sophisticated, tailored

suit – a suit that has been given an exclusive touch though Swarovski trimmings on the

front, side and rear lamps and the wheel rims.

But the crystal manufacturer came up with

a real masterpiece in the design of the seemingly never-ending 3D rear decorative panel.

The interior fittings of the “zaZen” are also dominated by this ethos of transparency and

reduction to essentials, cleverly combined with strategically placed highlights. The

transparent plastic seat shells of Makrolon® fitted with Technogel ®

upholstery were produced in cooperation with Recaro.

A bright, friendly mango-orange color has been chosen for the rest of the leather/fabric interior trim. It was made by hand by Strähle &

Hess, SC Schäfer, OesterleSLR and Sellner. Together with the Luoro Faia plantation

wood – also in the dashboard area – it creates an interior that radiates warmth and

relaxation.

The “zaZen”, which weighs 1,495 kg, is powered by a 355 bhp 6-cylinder boxer engine

from the Porsche 997 Carrera S. It has a top speed of 293 kph and accelerates from 0 to

100 kph in exactly 4.8 sec. Should the “zaZen” be built in a small series at some time in

the future, Rinspeed will consider – in line with its tradition – offering it with an

environmentally friendly natural gas propulsion system.

At 6,600 rpm, the engine has a maximum torque of 400 Nm, which is transmitted to the

rear axle via a manual six-speed transmission. The necessary traction is provided by

Dunlop tires with Touch Technology (245/30-20 at the front and 305/25-20 at the rear),

mounted on lightweight Rinspeed five-spoke rims (8.5 x 20” at the front and 11 x 20” at

the rear) made by CW Fahrzeugtechnik (Borbet Group).

The body – for which the molds were produced using Obomodulan ® modeling foam – sits

on a 4x adjustable chassis specially designed by KW automotive. Here, the designers

have managed to perform the rare feat of creating an outstanding synthesis of drive

comfort and sporty handling.

Another small work of art connected with the “zaZen” is currently taking shape in Berlin at

the eyewear designers, “ic! berlin”. The company’s owner, Ralph Anderl, who also acted

as the model during the photo shoot, was so taken by the new Rinspeed concept car that

he designed an eyewear collection specifically to go with the car. Now you can not only

drive the “zaZen”, you can also wear it.

Swiss made

Esoro

Frank M. Rinderknecht used highly advanced technology and a Swiss-based network of

top automotive specialists for his project. Although there is no automobile production in

Switzerland, there is a very active automotive supply industry there. Many highly innovative prototypes

have been developed and manufactured in Switzerland.

engineered by Esoro – What you dream is what you get

For the seventh time the Swiss engineering company Esoro was hired to serve as general

contractor for the entire vehicle project. Esoro was responsible for project management,

implementation of new technologies, engineering, design and manufacturing of the

Rinspeed “zaZen”.

Esoro realized the concept with the help of its highly competent suppliers Schwaller AG

(metal works) and Protoscar (styling). Starting with initial concepts, it took the highly

skilled development team just six months to realize the entire project.

Esoro has been a contract developer in the areas of automotive production, lightweight

design and plastics technology for 15 years. During this time it has gained a well-deserved

reputation for excellent efficiency and innovative solutions not just in these but also in

other fields, including fuel-cell vehicles and prototype design. Esoro has impressively

demonstrated its expertise with numerous extraordinary prototypes.

Another recent development from Esoro is the new E-LFT production technology

developed for Weber Fibertech. E-LFT makes large scale production of high-strength and

lightweight composite parts affordable. E-LFT composite parts weigh 30-50 percent less

than comparable steel parts. The first industrial part produced with E-LFT will be

introduced with the new Smart for two in 2007.

Furthermore another production process for niche markets, like high performance cars,

trucks and caravans is now introduced by Esoro to several OEM’s. The new and patented

process called Melt Embossing does offer the possibility to produce high end

thermoplastic composite parts with low initial invest for structural and semi-structural

applications. Esoro is able to offer the entire service starting from topological optimization

and explicit FE calculations trough to the delivery of the serial parts.

Strong partners for the future

Gasverbund Mittelland AG, Swiss Energy, Rinspeed and Volkswagen – four strong

partners – have the goal to develop vehicles that can be used on an everyday basis but

that also depict automotive visions for the future. The exhibited vehicles are operated

ecologically with natural gas or biogas as the fuel of choice. With the exception of the

zaZen which can also be converted to natural gas operation.

The power supply company Gasverbund Mittelland AG has promoted the marketing of

natural gas as a fuel in Switzerland for many years first-hand and also as gasmobil ag’s

partner. Natural gas is currently the only available, sensible and environmentallycompatible fuel alternative that contributes significantly to a decrease of noxious

emissions in particular in heavily populated regions. Furthermore, noxious particles can be

further reduced in combination with the CO2-neutral biogas.

Speed limits as result of critical particle emission values would be less of an issue. The most important arguments

for natural gas and biogas as fuels are: more than 60 percent reduction of noxious

emissions compared to petrol or diesel; even less fuel consumption for mixed operation.

This results in savings of 30 to 40 percent of fuel costs. Tests have shown that natural gas

vehicles are just as safe as the same models with a petrol or diesel motor.

Dunlop

Dunlop, one of the world’s leading manufacturers of high performance tyres, is tyre

partner of the exciting “zaZen”. The new Rinspeed “zaZen” is equipped with Dunlop’s top

of the range ultra-high performance summer tyre SP Sport Maxx, a tire with excellent

performance especially in dry handling, SP Sport Maxx is designed to guarantee all

drivers outstanding road feedback. At its stand 1011 in hall 1 Dunlop is launching Touch

Technology. Touch Technology reflects Dunlop’s product development approach: Dunlop

tyres enable drivers to have an enhanced feel of the road, to be more in control of the

drive and to have more fun on the roads. The “zaZen” is fitted with SP Sport Maxx in the

sizes 245/30-20 (front) and 305/25-20 (rear).

KW automotive GmbH

Visionary thought and action is what links company founders Frank M. Rinderknecht of

Rinspeed and Klaus Wohlfarth of KW automotive GmbH in Fichtenberg (Baden

Württemberg). The result for their customers is innovative designs and engineering

innovation at the highest level.

For that reason it was a matter of course for KW automotive GmbH once again to equip

the latest Rinspeed concept car, the “zaZen”, with KW adjustable coil over suspension in

“inox line” stainless steel technology, damping variant 3. In this case innovation also

extends to the materials used – KW now produces all its adjustable suspension systems

only in stainless steel, as this offers significantly higher corrosion resistance compared

with galvanised designs. That is certainly in the customer’s interest.

As to the suspension itself, it is a high-tech product developed by the KW engineers, which can be completely adjusted to suit the individual driver’s requirements. Everything is possible, from extremely luxurious to extremely sporty. Version 3 is infinitely heightadjustable on the front and rear axles, and has separately adjustable compression and rebound mode damping. The adjustment in compression mode is carried out at the bottom

end of the shock absorber by means of the patented multiple valve. This suspension

system provides the technically demanding driver with “high tech” from the world of motor

sport, enabling the driver to customise the vehicle’s handling characteristics to suit

him/herself.

KW automotive GmbH has for many years been a byword in the industry for premium

products in the field of car tuning. The company offers its customers the largest range of

adjustable suspension systems. The whole range – from springs and sports suspension

systems to adjustable suspension systems in three damping variants – is unequalled on

the market in its scope and variety. With its engineering competence and its range of

available products, KW covers the requirements of both popular and top-level sport in

terms of motor racing technology.

There are now over 100 employees at the company’s

headquarters in Fichtenberg, ensuring that top-quality products continue to leave the

plant. KW automotive GmbH has established plants at five different locations worldwide,

and now employs a total workforce of 180 – and that is a rising trend.

Color design inspired by Far-Eastern philosophy – Lesonal develops colors for

Rinspeed

Working in close cooperation with the renowned Swiss car tuner Rinspeed, paint

manufacturer Lesonal created the color design for the Rinspeed concept cars. Lesonal

exclusively supports Rinspeed with a custom color design for eco-friendly VW project

vehicles finished with the Lesonal paint system.

The Buddhist Zen philosophy focuses on the essentials. This theme served as the

concept for developing the Rinspeed K2 special effect color. The Lesonal color design

was inspired by the teachings and nature of the Far East. Lesonal product manager

Thomas Kalan describes the unique finish: “The fine rainbow shimmer of what initially

appears to be white is derived from Himalayan glaciers.

This special effect paint was

inspired by the color spectrum of the snow-covered K2. Similar to the iridescence of

glacial colors, the effect really comes to life when one takes a second, deeper look.”

The “zaZen” project represented a major challenge. This futuristic “zaZen” concept car will

be presented to the public for the first time at the 76th Geneva International Motor Show.

Using precious Swarovski crystals, the “Crystal Skin” effect was developed and

implemented by color and paint specialist Karl Seelos from Fritzens, Austria. This

exclusive color shade requires a perfectly smooth surface. Lesonal responded to this

need by supplying the best possible surface.

“zaZen” – Seat-Zen

With the concept car “zaZen”, Rinspeed is now exploring a new route in automobile

development. In the face of information overflows, time pressure and ever more buttons

and displays in the vehicle, the Swiss vehicle refiner is concentrating on the essential with

the use of innovative technologies. The aim: to allow the driver to concentrate on the

essential – the Zen.

The seat is the largest area of contact between the occupant and the vehicle and, as

such, plays a particularly important role in this concept. Recaro, leading innovator in

automobile seat construction, uses “glass” seat shells made from Makrolon® and bright,

cheerful upholstery made from transparent Techno-Gel, allowing the seat to adapt

automatically to the occupant. In this way, the interior establishes a meditative link

between man and machine. Normal seats are transformed into relaxed seating based on

“zaZen” – the Japanese word for seated meditation.

With this project, Recaro is implementing a new form of innovative technology and taking

a major step closer towards to the ultimate goal of “Made-to-Measure seating”.

Today as in the past both automobile manufacturers and end-consumers regard Recaro

as a pioneer among seat manufacturers with regard to quality, safety and innovation.

About the company: Recaro is an independent company within the internationally-active

Keiper Recaro Group. Just under 8.000 employees work in the three divisions Keiper,

Recaro and Recaro Aircraft Seating to ensure high-quality products in the field of mobile

seating for aircraft and vehicles. In 2004, the group made a turnover of one billion Euro.

Recaro has a long tradition: The firm was founded in 1906 by saddler Wilhelm Reutter as

a car-body production plant and can look back on 100 years of company history. Reuter

produced car bodies for vehicles such as the Porsche 356, VW Beetle, BMW 328, Horch

and many other well-known brands.

The Recaro brand name was created by combining

the first two letters of the founder’s name with the first four letters of CAROsserien, the

German word for car body. The first Recaro sports seat was presented in 1965. Following

the merger with Keiper in 1969, Recaro has been active as an independent member of the

Keiper Recaro family, defining automobile seating with many revolutionary innovations.

Revoflex AG

Visionary and innovative projects call for visionary and innovative solutions.

A world novelty: holographic brake lights for cars, combined with a very flowingly

designed, one-piece roof structure made from the hi-tech substance Makrolon.

This calls for crystal-clear and extensible sealing and adhesive materials for the transition

from the roof to the car body, which is painted with millions of minute high-quality

Swarovski crystals.

As Swiss specialists for out-of-the-ordinary technology, the engineering Group Revoflex

AG has developed a completely new and crystal-clear solution to cover the sealing and

adhesion requirements, with a view to facilitating our vision – a completely transparent

“body of light” on four wheels -down to the last detail. This involved the customized

development of a special, crystal-clear and elastically extensible adhesive for the

Makrolon substance produced by Bayer Material Science, one of the major plastics

manufacturers of the world.

The result was a highly innovative product, in which nanocomposites were united in combinations of substances never seen before.

In the interests of a successful two-way partnership, in which the central focus is on the

customer and his project, Revoflex has organised support and service on a holistic basis,

from development to prototype manufacture and right through to the end product.

Our vision: Revoflex realises innovative solutions in plastic materials in order to fulfil the

customer’s requirements in the best possible way.

Our strategy: We create added value for our customers on the basis of long-term

partnerships.

We achieve this with the help of

innovative competitive solutions

rapid and flexible realisation, up to and including market publicity

use of ideal technology

our own standardised techniques

Structure: Revoflex is an innovative company which works as a network to meet the

requirements of our customers – rapidly, efficiently and sensitively. Our head office is

responsible for the coordination of all production projects, and for the realisation of our

innovative technological solutions.

The Ultimate Auto Finish

Tyrolean company perfects crystal coating for cars

When the zaZen auto by Rinspeed is unveiled at the prestigious Geneva Motor Show, it

will reveal an unmistakable crystalline luster that speaks of pure auto glamour. The

surface of this car is coated with thousands of Swarovski crystals and is the brainchild of a

Tyrolean company run by Karl Seelos and his team.

Seelos, a specialist in auto modification, decoration and embellishment who names

members of the British, Brunei and Saudi royalty among his clients, has created the

special “Crystal Skin” used on the Rinspeed car. The process involves integr ating

thousands of tiny crystals used on Swarovski’s “Crystal Fabric” into the surface of the

paint. The base color, while being embellished with the crystal effect, remains intact and

an additional transparent sealer covers the crystalline surface to result in a mirror smooth

surface. The result is a glittering surface that still allows the beauty of the originally chosen

color to shine through.

Technical innovation, feeding the senses and the environmentally friendly concept

correspond to the values of Sharp in a high degree. The multimedia-partnership Sharp

and Rinspeed shows this to the public.

At events and exhibition Sharp Aquos LCD-TV will help the audience to understand and

experience the zaZen.

Swarovski

Futuristic auto with crystal features for Geneva Motor show – Swarovski cooperates on

zaZen project

When one of the world’s most futuristic autos is unveiled at the renowned Geneva Motor

Show on February 28, 2006, lovers of superb machinery will be introduced to a car that

deploys innovative use of Swarovski crystal. The car, the zaZen, produced by the Swiss

company Rinspeed not only uses innovative crystal paint and attractive crystalline

decorative features, but also advanced crystal and LED technology for it’s lighting system.

Revolutionary new design

The zaZen, a reference to the Buddhist teachings, is a revolutionary new design concept

for the automotive industry. This sleek machine features a roof dome down to the belt line

that is made from a single sheet of transparent Bayer polycarbonate. Occupants sit on

glass-like plastic seat shells in cheerful, friendly orange, with crystal applications on the

backside.

Crystal brilliance for technological advancement

An essential part of the zaZen’s organic design is its fascinating mineral white color which

is both understated and beautiful. The effect is created using millions of tiny Swarovski

crystals protected by a self-healing polyurethane clear coating.

Other crystalline features on the car includes wheel rims using the company’s Crystal

Fabric in orange, the theme color for indoor features, and a continuation of the clear

crystal body work. The car’s hubcaps are also crystal embellished in the center and the

latest crystal and LED lighting techniques have been deployed for the headlights, rear

lights and the side indicators. In addition, the “zaZen” name plate on the rear of the

vehicle is made up of a crystal panel with endless effect.

Swarovski as innovator

Swarovski, the world leader in crystal manufacture has made it a cornerstone policy to

constantly seek out new ways of using crystal for decorative, design and practical

purposes. This can only be achieved through a dedicated commitment to innovation and

trend research. The zaZen project is the fifth such activity undertaken by Swarovski,

together with Rinspeed, in the exciting field of futuristic autos.

For more than a hundred years Swarovski, the Austrian family company based in Wattens

in the Tyrol, has been the world’s leading brand for cut crystal. Crystal jewellery stones

and crystalline semi-finished goods for the fashion, jewellery and lighting industries are as

much a part of the company’s product range as gift articles, home accessories, and

collectibles fashioned from faceted crystal. Swarovski’s artistic and design abilities are

evident in Daniel Swarovski Paris and Swarovski Jewellery, the company’s accessory and

jewellery ranges. Since 1995 visitors have been able to enjoy the ultimate crystal

experience at the Swarovski Crystal Worlds.

The Swarovski group also includes Tyrolitâ,

which produces grinding tools and abrasives, and Swarovski Optik, the company’s optics

division, with its precision optics for hunting and nature observation. In 2004 Swarovski

achieved group sales of Euro 1,83 billion with a total of approximately 16,000 employees.

Refined crystal mobile phone – Motorola presents its cult RAZR V3i mobile phone in

refined Swarovski look

Thousands of tiny Swarovski crystals adorn the new limited edition of Motorola’s RAZR

V3i multimedia cell phone. In collaboration with Rinspeed, Switzerland’s top creative

design factory for cars and automotive accessories, the RAZR V3i is to be given a unique

superior finish.

Two versions of the cult phone – sparkling white and mango/orange – will

go on show at the Rinspeed stand at this year’s Geneva Motor Show from 2 to 12 March

2006. Rinspeed will be presenting the designer car to match the phone – the “zaZen”, a

design prototype, which features the same high tech finish and whose revolutionary

lighting technology is a real eye-catcher.

The refined Swarovski look perfectly complements the design of the Motorola RAZR V3i.

In addition to the glittering crystals, the phone’s keypad reflects the incoming light, while

the blue backlighting defines each character and key. In a groundbreaking use of material,

a revolutionary etched keypad has been created – fashioned from a single sheet of metal -giving the Motorola RAZR V3 family an unmistakable design presence.

Connected in style – all around the world

The Motorola RAZR V3i has plenty to offer technology-wise, too. The RAZR V3i

combines exceptional form with high-performance Bluetooth technology, allowing users to

enter a world where voice, image and video are easily transmitted without wires – smart

and ever-so stylish. Photographers are particularly well-served: A 1.3 megapixel camera

lets you take brilliant photos, which can be stored on the TransFlash memory card that

comes as part of the package. The quad-band technology keeps you connected in more

than 100 countries worldwide and means you can travel around without ever missing a

call. The improved battery life with 310 hours of standby time makes sure of that.

Websites:

Obo Werke GmbH & Co.KG – www.obo-werke.de

CW Fahrzeugtechnik – www.borbet.de

Dausmann Holographics GmbH – www.dausmann-holographics.de

D. Swarovski & Co. – www.swarovski.com

Dunlop – www.dunlop.de

Erdgas – www.gvm-ag.ch

Esoro AG – www.esoro.ch

ic! Berlin – www.ic-berlin.de

KW automotive GmbH – www.kw-gmbh.de

Lesonal Gmbh – www.lesonal.de

Motorola – www.motorola.ch

Protoscar SA – www.protoscar.com

Recaro GmbH – www.recaro.com

Revoflex AG – www.revoflex.ch

Seelos : www.seelos.net

Sharp Electronics – www.sharp.ch

Strähle + Hess GmbH & Co. KG – www.straehle-hess.de

OesterleSlr – www.oesterleslr.de

Sellner GmbH – www.sellner.de

SC Schäfer – www.sc-schaefer.com

Technogel Germany GmbH – www.technogel.de

Tom Burkart is the founder and managing editor of Car-Revs-Daily.com, an innovative and rapidly-expanding automotive news magazine.

He holds a Journalism JBA degree from the University of Wisconsin – Madison. Tom currently resides in Charleston, South Carolina with his two amazing dogs, Drake and Tank.

Mr. Burkart is available for all questions and concerns by email Tom(at)car-revs-daily.com.